Furnaces and fireplaces

When used in the process heating furnaces to assess the condition of the lining is very important. There are clear links between the temperature distribution of the masonry and its condition. Hot spots suggest increased wear. The early detection of such bodies is a problem with the use of thermography systems and it can be taken measures to reduce the damage progression.

Suspicious damage hot spots are in the planning of quality material? and maintenance capabilities included. To limit damages to be solved economically. In addition, a sophisticated exploitation of the remaining life of the plant is possible. In studies with fireplaces thermography for detection of deposits are made. Figure 6 shows an industrial chimney with heavy deposits in the lower region, which also reduce their insulating the outside temperature.

The investigations made to serve as an indication of possible flow-related, procedural problems, and secondly as a basis for planning the removal of such deposits, that is for preventive maintenance.

Glass manufacturing

With the optimized production of front and rear windows for installation in automobiles are heating and cooling processes to perform the windows. In these operations, certain temperature distribution pattern can be reached on the disk surface. The only way to shaping and cooling take place optimally.

The use of thermography systems provides information on the temperature distribution on the glass. Thus, small changes of the thermal conditions are identified and considered.

In a heated rear window thermography systems are used to verify that the heating wires to distribute the heat evenly over the whole disc. Broken filaments are detected it.

Besides the quality assurance is heat flow measurement in the manufacture of glass, ie in furnaces and rolling, used.

Surface Temperature Measurement of through flames with Thermal Imaging Camera

Radiometric infrared thermal imaging cameras with specially adjusted wavelengths are used for hand-held sampling purposes as well as for permanent installed “in-line” measurements.

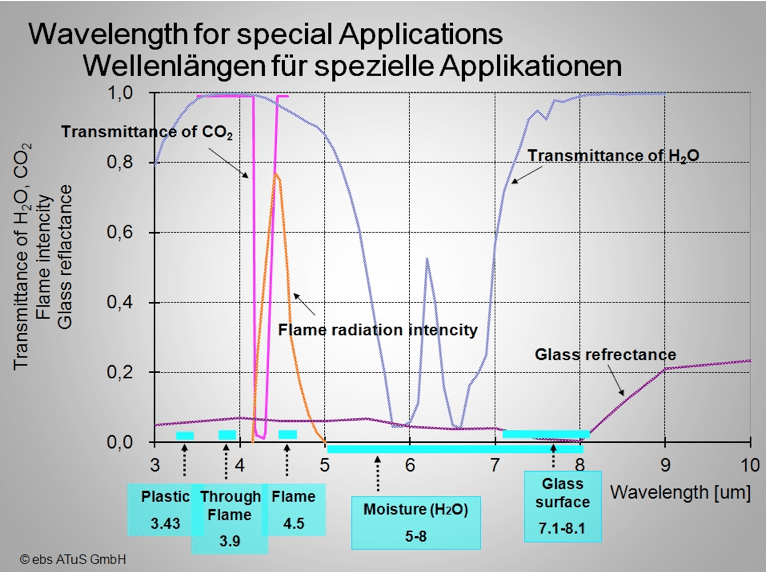

Correct temperature measurements in the infrared spectrum through flames, preferably would be taken at:

|

Wavelength of 4,5µm with a spectral window of approx. +/-100nm bandwidth. Under usage of concerted Infrared filters with limited band width, temperature deviations arising from the flames it selves, can herewith extensively avoided with conventional thermal imaging cameras. |

|

For reliable temperature measurements specific material parameters such as emissivity, temperature level and reflecting temperature have to be considered [TBC e.g. TRef) even the atmospheric compensation model [TAir (°C), Humidity (%), Distance (m)].

Surface Temperature Measurement of Glass(melting) with Thermal Imaging Cameras

Radiometric infrared thermal imaging cameras with specially adjusted wavelengths are used for hand-held sampling purposes as well as for permanent installed “in-line” measurements.

Correct surface temperature measurements in the infrared spectrum of transparent e.g. high-reflective materials such as glass(melting), preferably would be taken at:

|

Wavelength of 7.1-8.1µmwith a spectral window of approx. 1µm bandwidth.Under usage of concerted Infrared filters measured temperature deviations, arising from the background of any diaphanous objects or reflecting environment, over the entire wavelength range of a conventional thermal imaging camera, can be herewith extensively avoided. |  |

For reliable temperature measurements specific material parameters such as emissivity, temperature level and reflecting temperature have to be considered [TBC e.g. TRef) even the atmospheric compensation model [TAir (°C), Humidity (%), Distance (m)].

Related Products

-

Thermal Imaging Camera Avio InfReC R300BP-TF

The modular Infrared camera concept for special application and technical challenges. Wide band wave lenght of an uFPA allows measurements from 3µm -14µm and appropriate IR filters. The InfReC R300BP-TF uses 3.8µm for Through-Flame measurements FLIR - Forward Looking InfraRed - & IR Imaging & Infrared Thermal Imagers by ebs ATuS GmbH

info@irpod.net

info@irpod.net